We use cookies to help us deliver and improve this site. By clicking Confirm or by continuing to use the site, you agree to our use of cookies. For more information see our Cookie Policy.

04 Aug 2025

Update on Specialist chocolate Pump Range from Viking Pump

Michael Smith Engineers announces an update on Viking Pump’s highly popular dedicated Chocolate & Confectionery Series, designed to meet the precise demands of chocolate production and processing.

The range includes the 1224A-CHC® Cast Iron Series and the 1227A-CHC® Stainless Steel Series, both featuring Viking’s patented double O-Ring “O-Pro® Barrier Seal” technology for reliable, leak-free operation. Capable of handling viscosities up to 200,000 cSt and flow rates of 0.2–90 m³/h, these pumps are purpose-built for applications such as chocolate liquor, cocoa butter, and pastes.

Maintenance-friendly features, such as in-situ O-ring replacement and retrofit kits, mean operators can minimise downtime and extend service life. With their combination of performance, durability, and ease of service, Viking Pump’s Chocolate & Confectionery Series delivers a dependable solution for the confectionery sector.

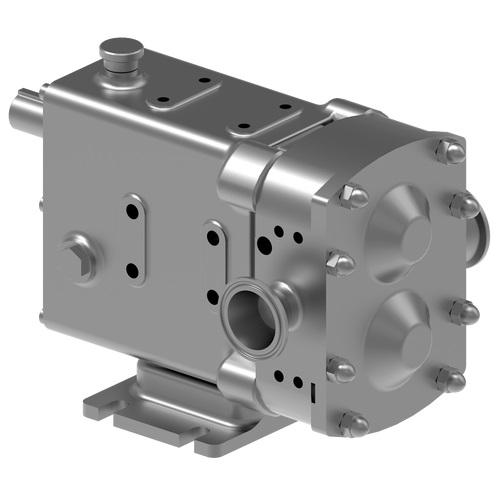

1224A‑CHC® Series (Cast Iron)

- Designed with a double O‑Ring “O‑Pro® Barrier Seal” to prevent shaft leakage and maintain strict hygiene

- Handles flows up to 400 GPM (0.2–90 m³/h) and viscosities up to 200,000 cSt

- Ideal for chocolate liquor, pastes, cocoa butter, lecithinapplications

1227A‑CHC® Series (Stainless Steel)

- Built with 316 stainless steel and O‑Pro® seal for improved durability and cleanability

- Suitable for temperatures up to 107 °C (225 °F), pressures up to 10 bar, and flow rates from 6–320 GPM (1.4–73 m³/h)

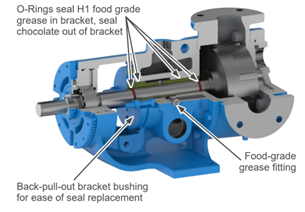

Innovative Design Enhancements

O‑Ring Seal Technology: The patented, retrofittable back-pull-out bracket seal houses grease between double O‑rings to eliminate chocolate migration and reduce slip hazards—also compatible with existing CHC pump brands via retrofit kits

Built-in Cleanability Features: Stainless steel construction and smooth internal surfaces support food-safety standards (EC 1935 compliance), while flush/suck-back grooves and drilled idler gears reduce product buildup and seizing

Thermal Management: Integrated head/bracket jackets allow chocolate liquefaction prior to startup to avoid damage to seals and ensure consistent product flow

Reduced Maintenance: O‑rings can be replaced with the pump mounted in place, grease nipples and relief fittings eliminate overpressure, and component kits simplify conversion and servicing

Viking Pump's Chocolate Series, including the 1224A‑CHC® and 1227A‑CHC® models, offers confectionery manufacturers:

- Reliable, leak-proof performance

- Optimized for a wide viscosity range

- Low-maintenance operation

- Full compliance with food-safety standards